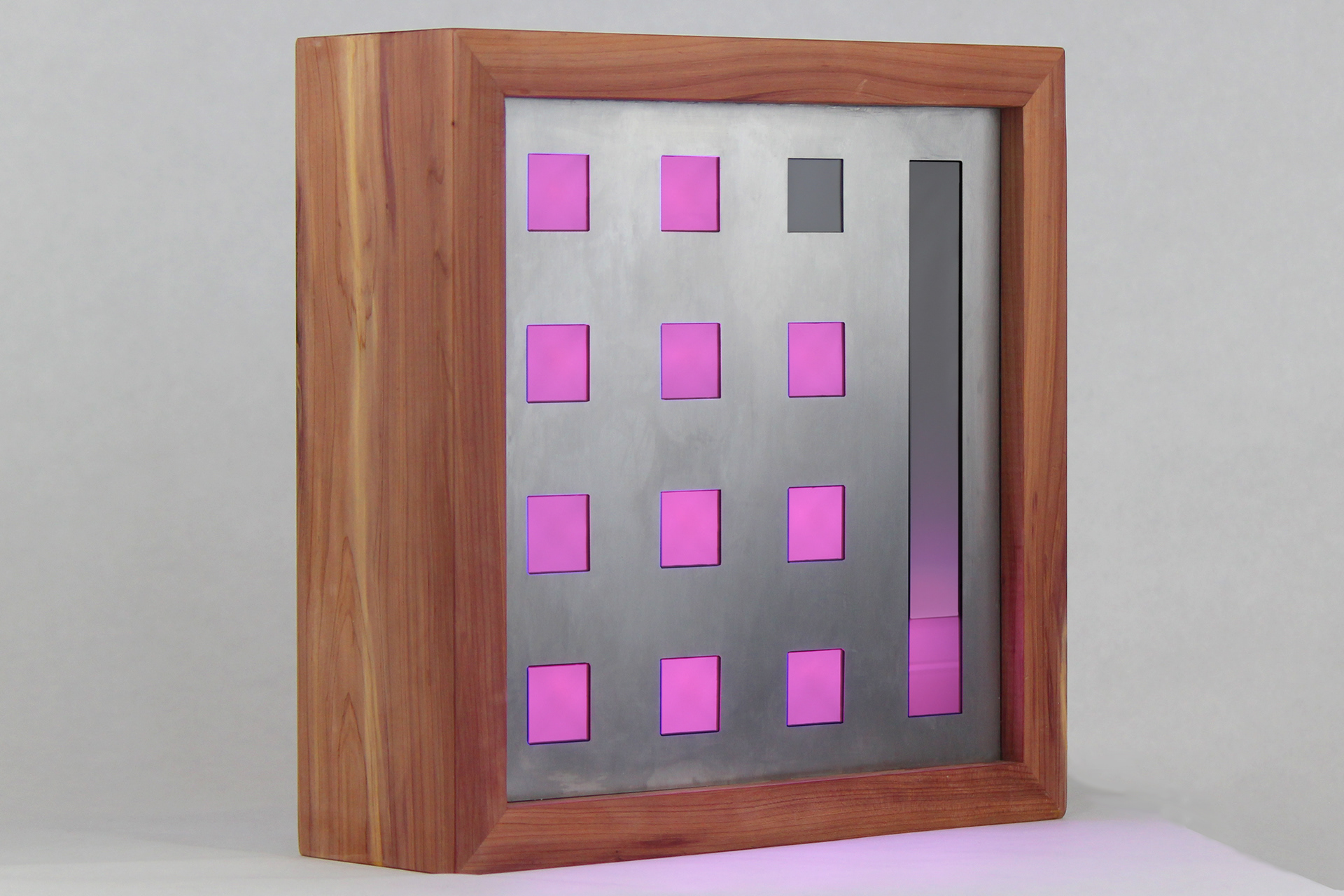

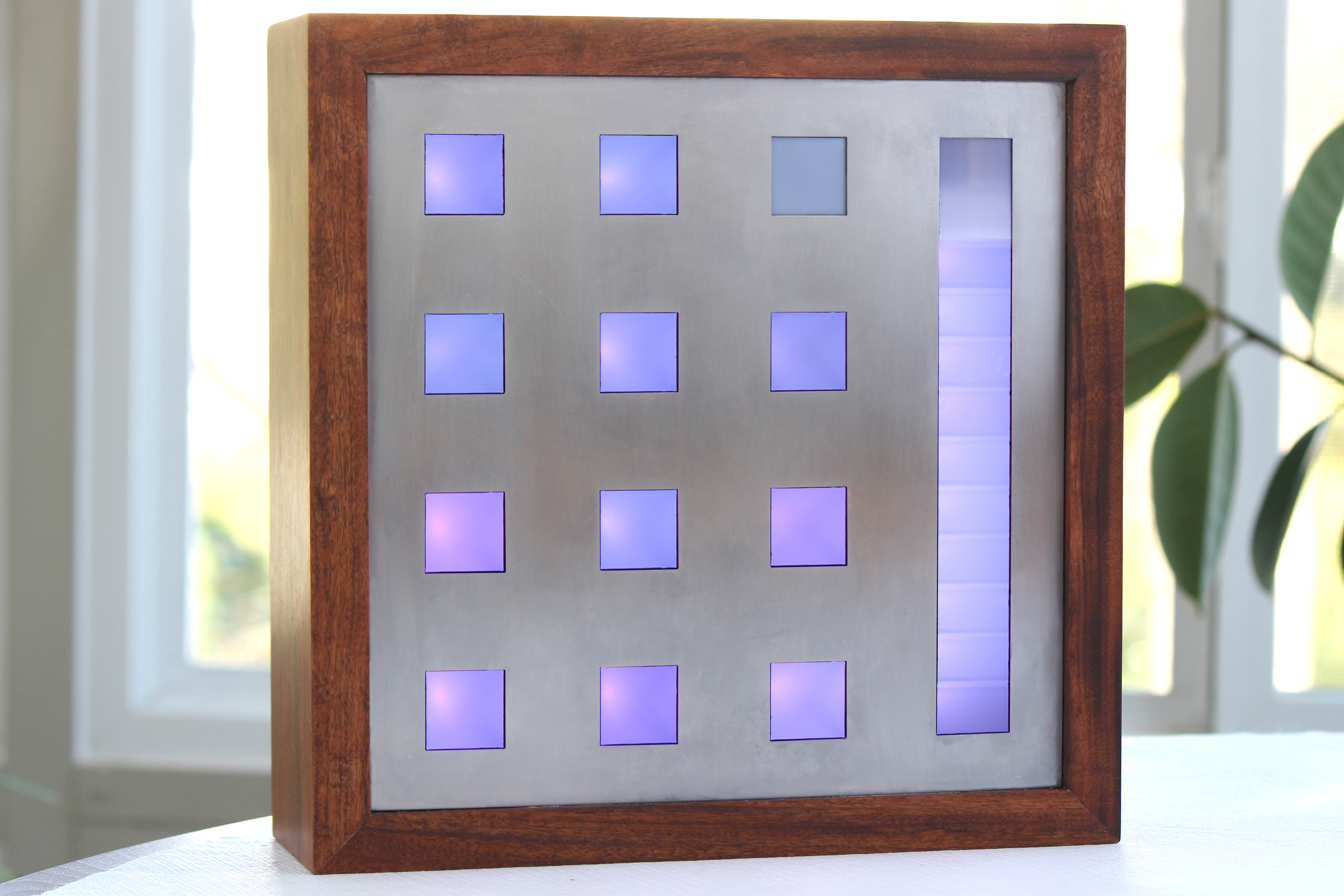

TEMPO

Westlake Industries

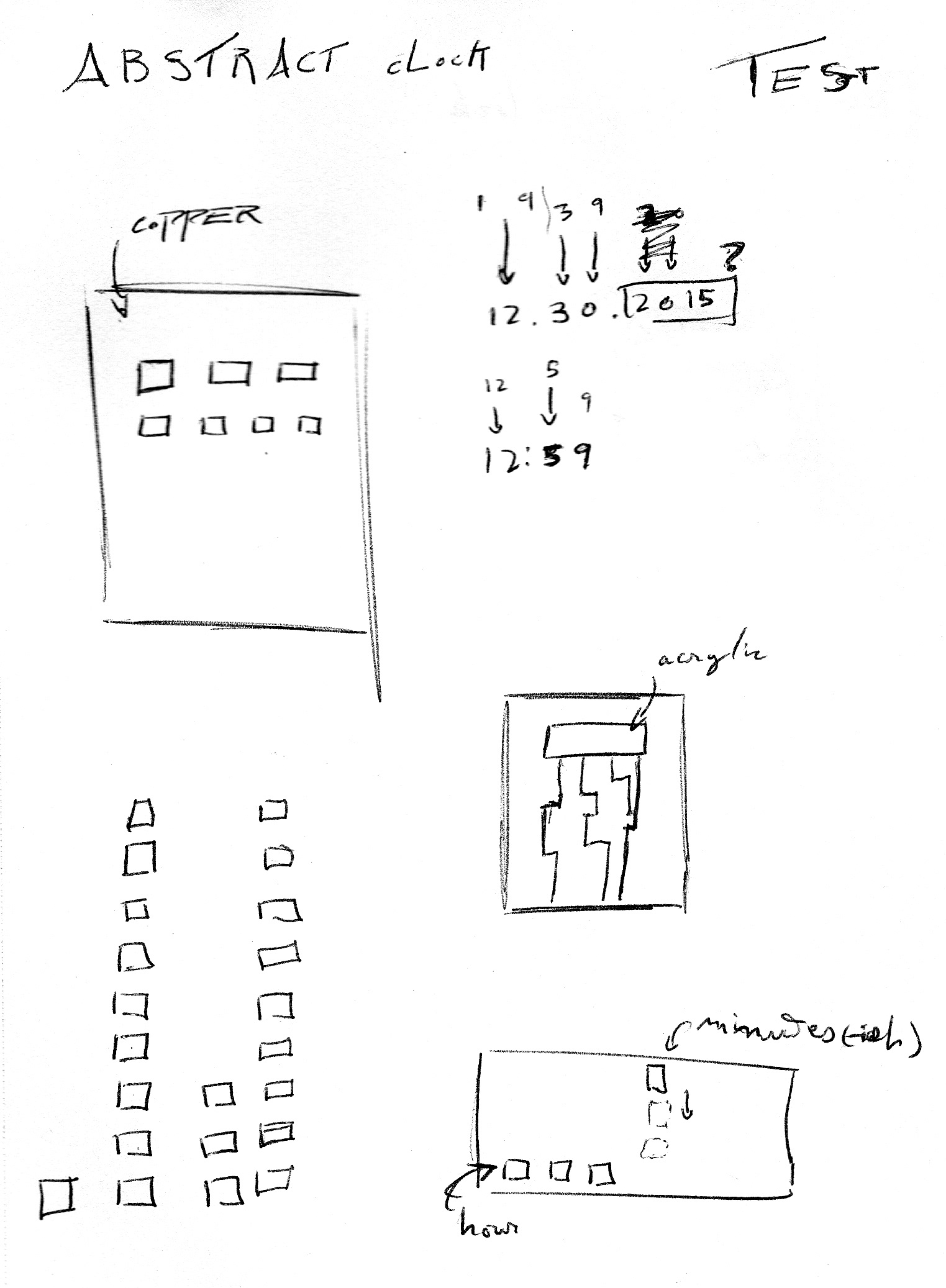

Tempo began life in 2014 during a senior design project at Georgia Tech. I was tasked with inventing and manufacturing 10 of a product. I wanted something that would combine my interests in woodworking, metal, and electronics.

The question I ended up asking myself was: in a world of smartphones, smart watches, and even smart appliances, what purpose does a stand-alone clock serve?

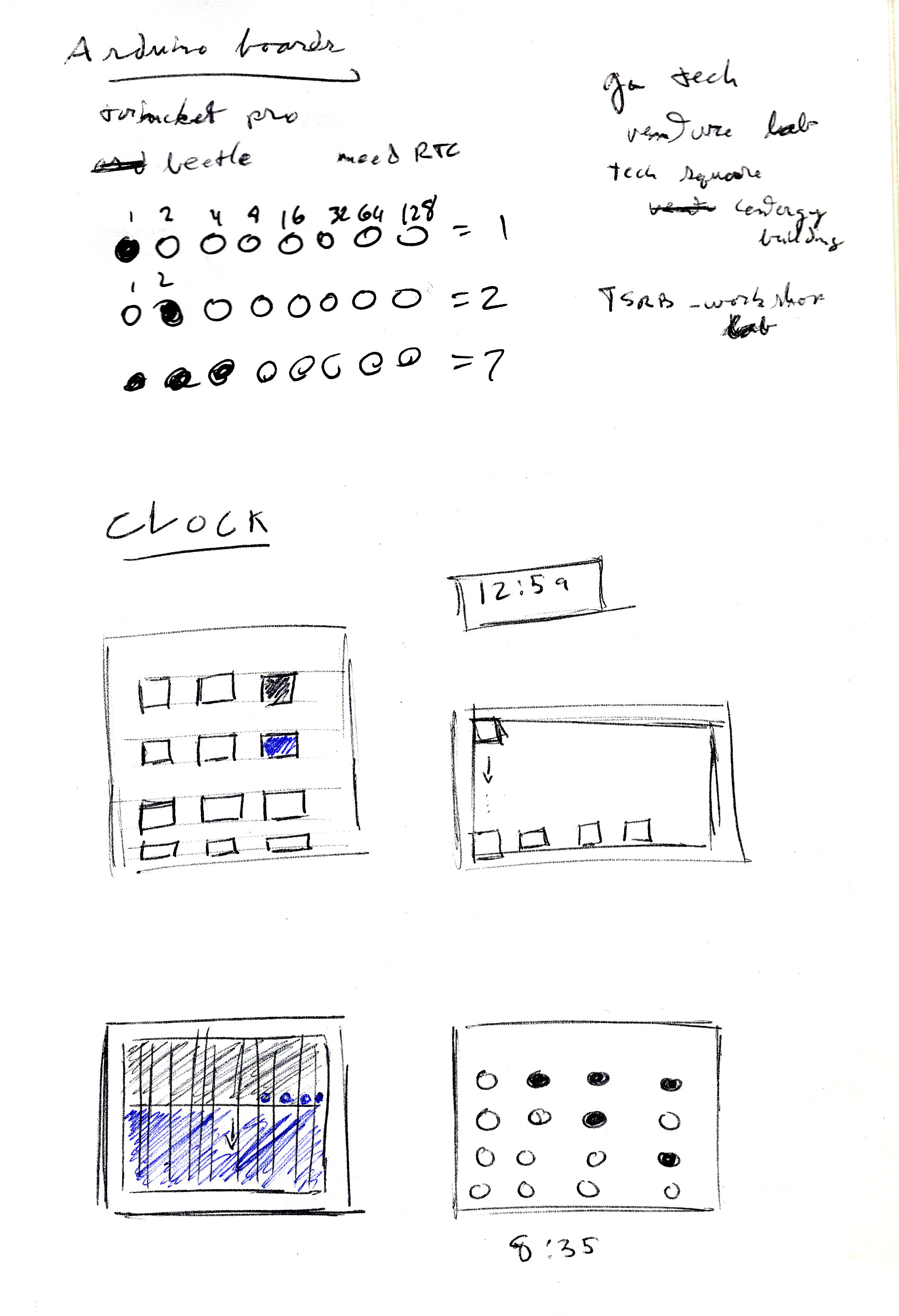

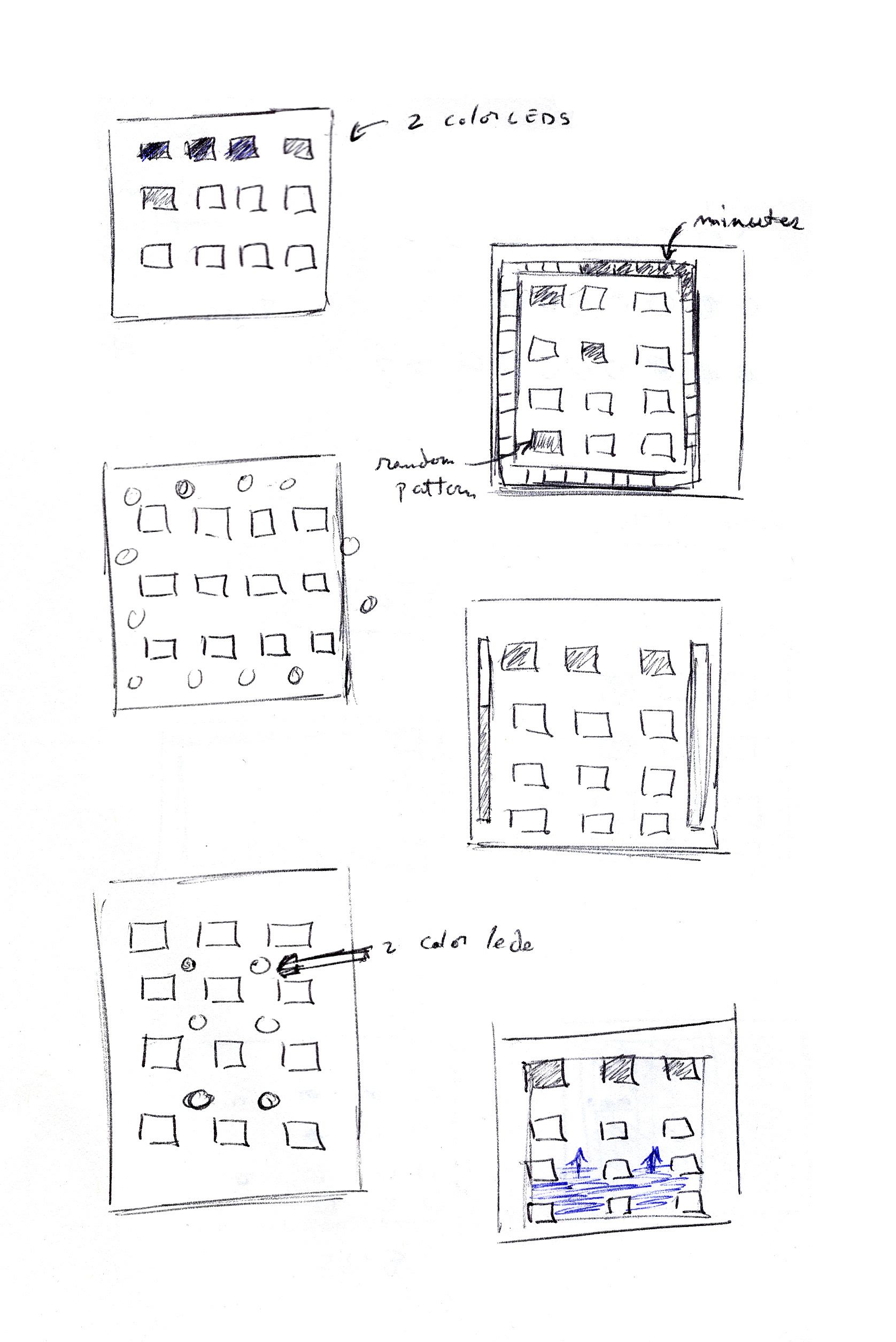

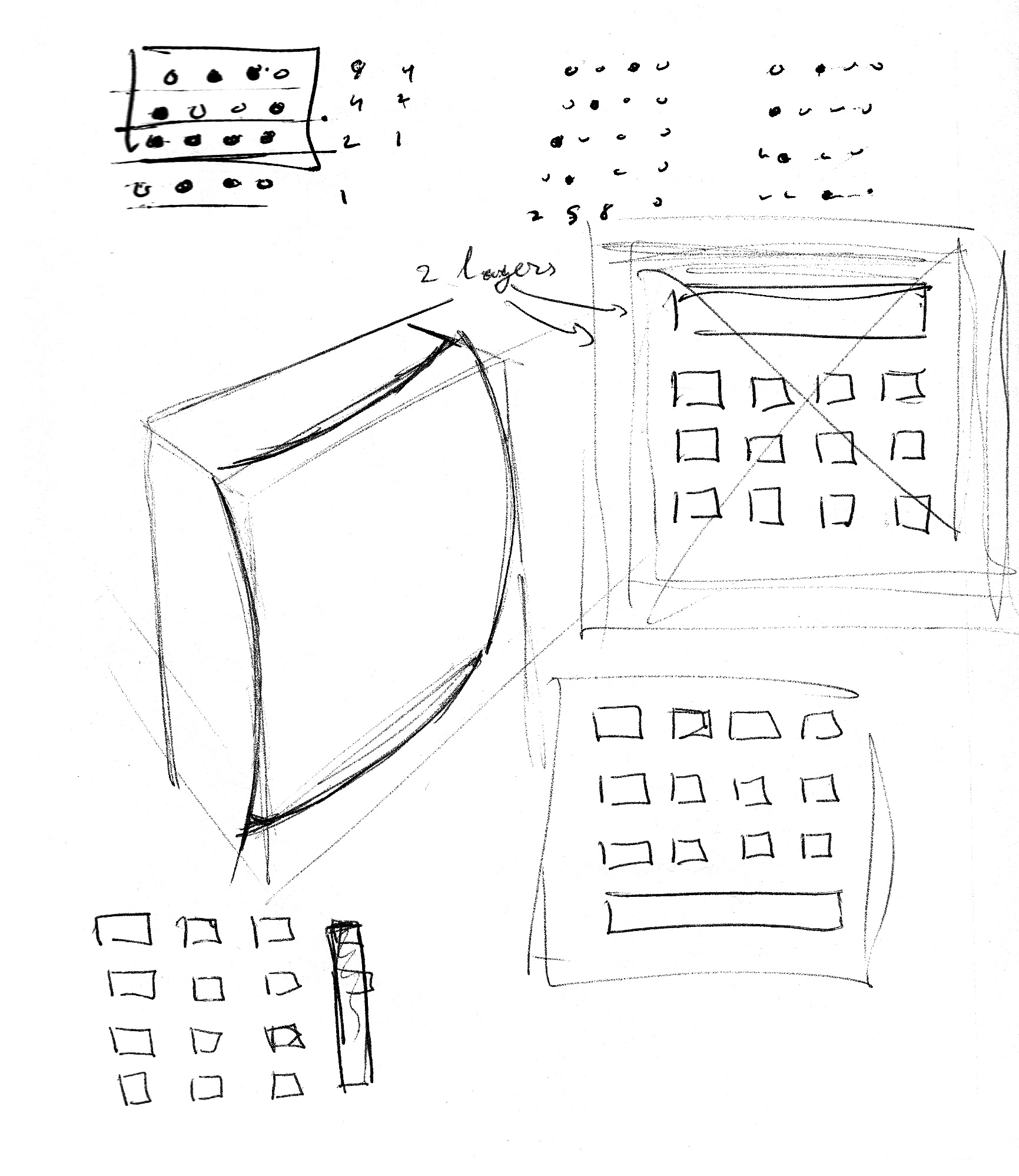

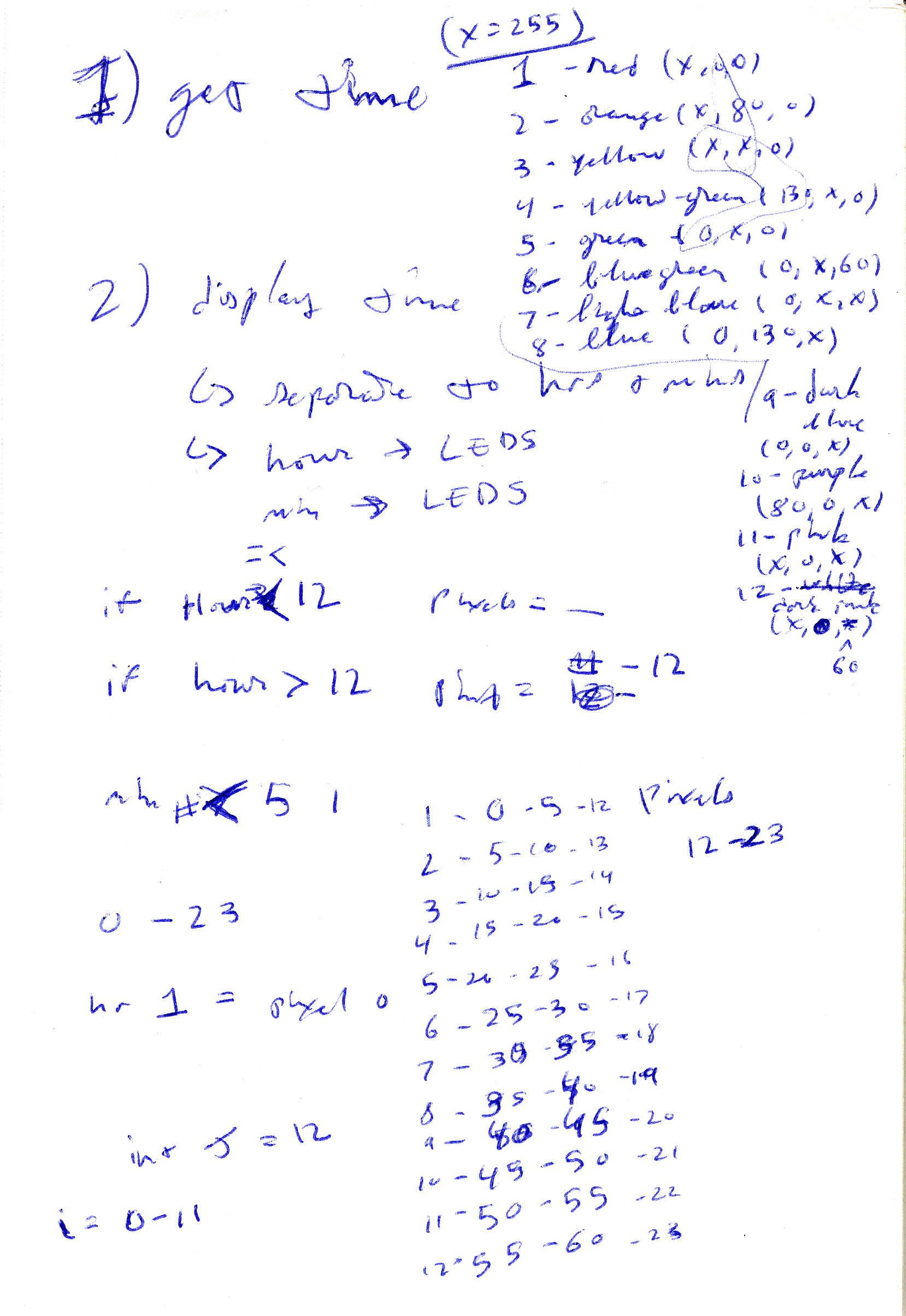

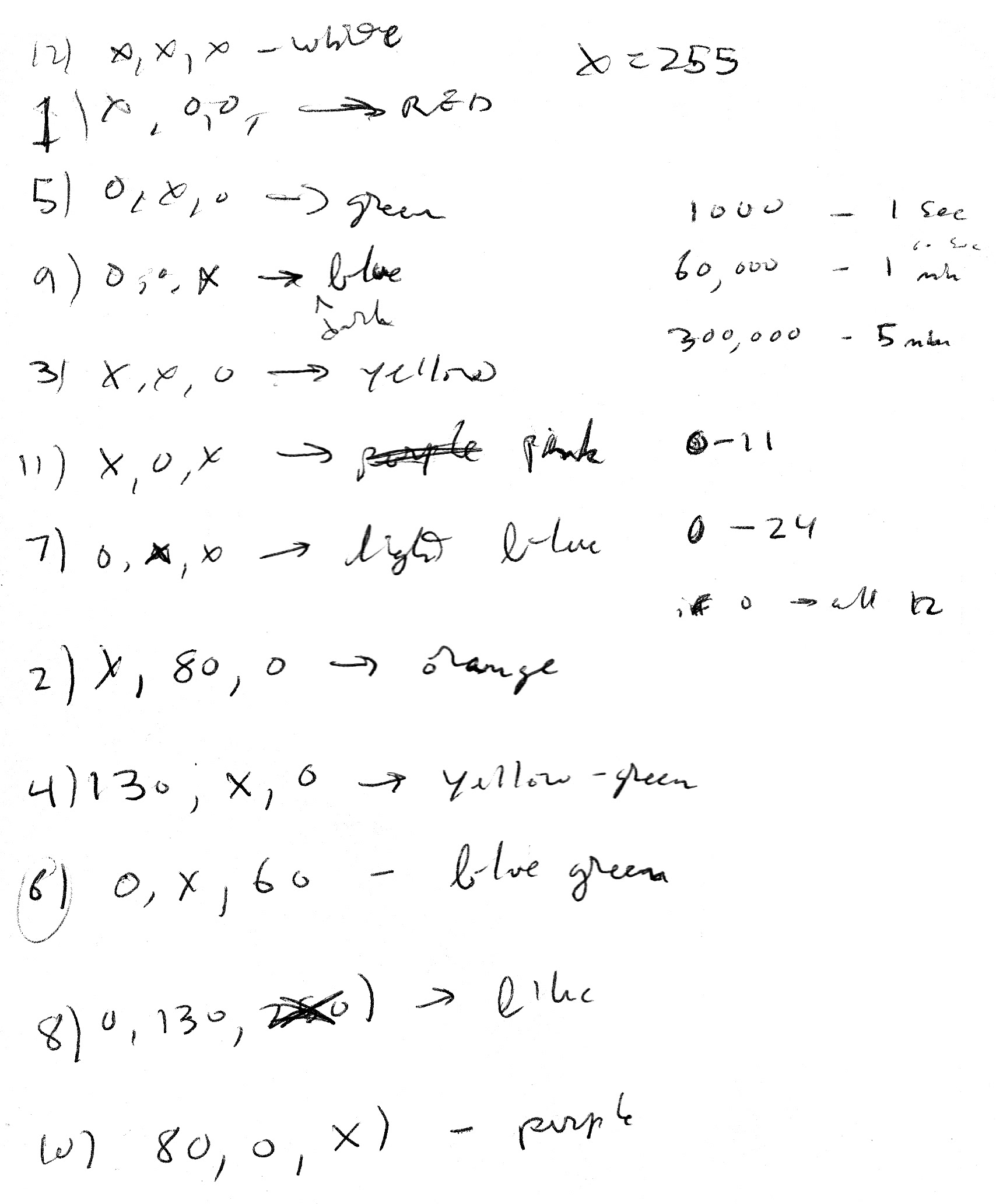

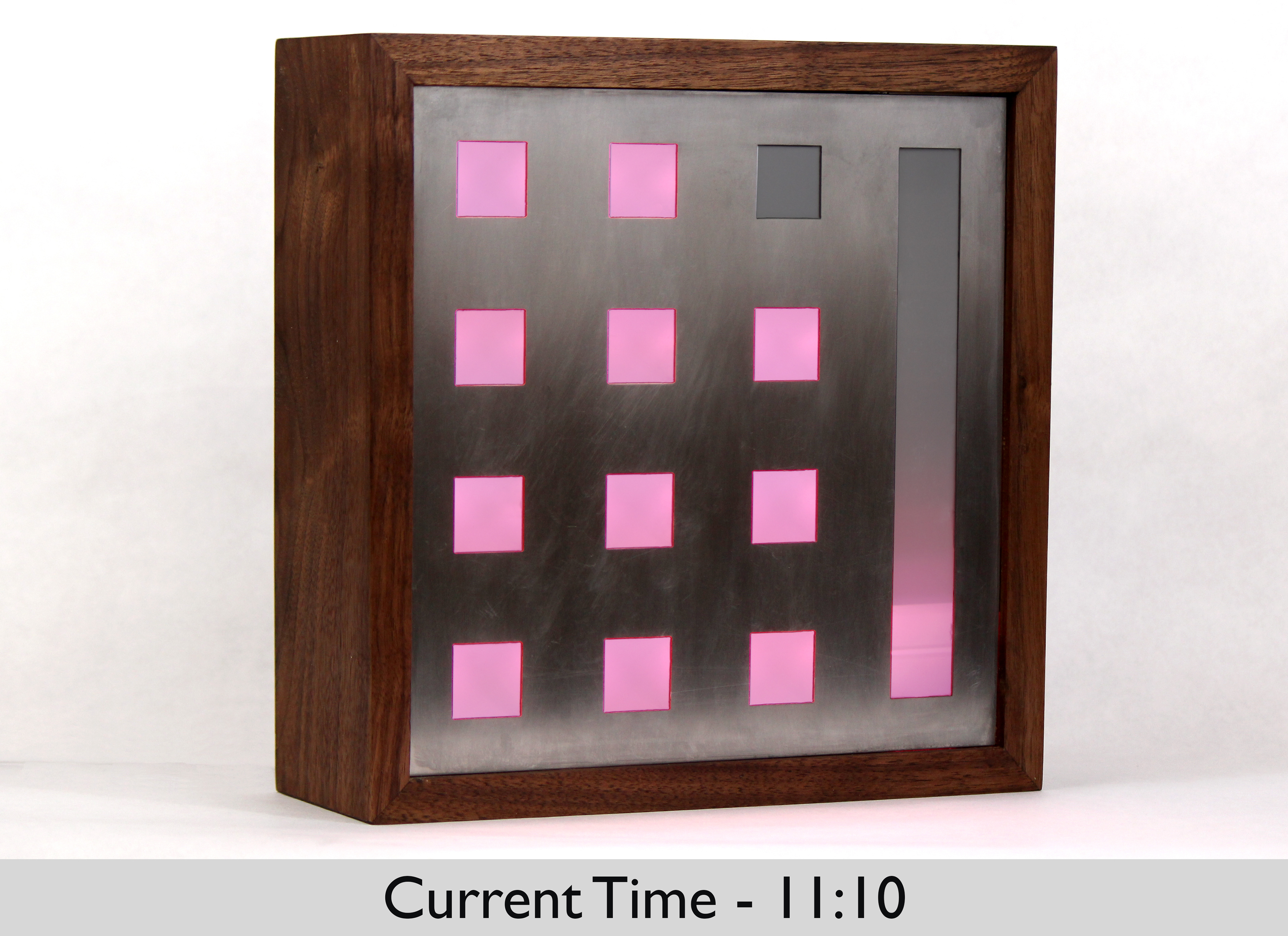

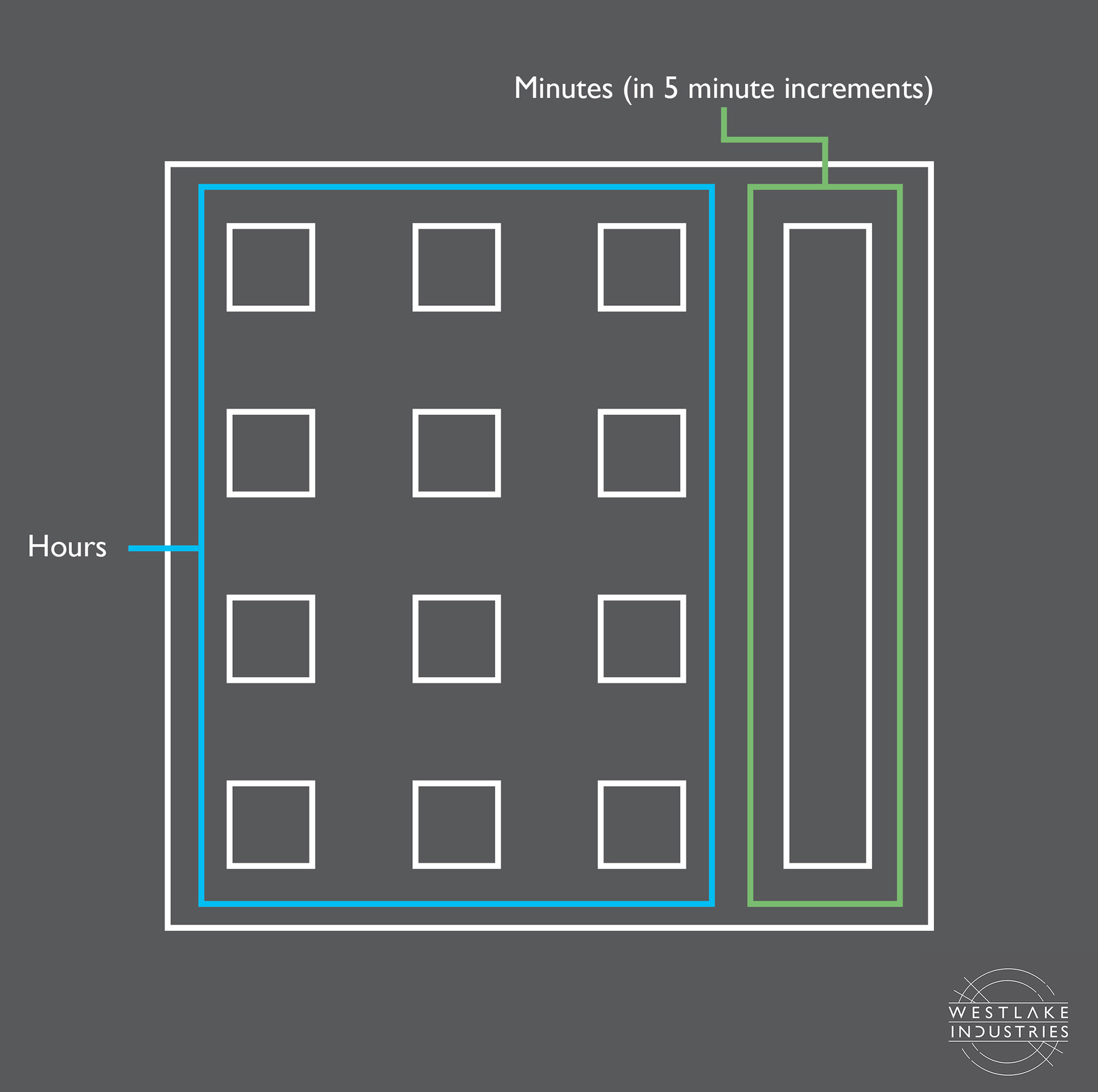

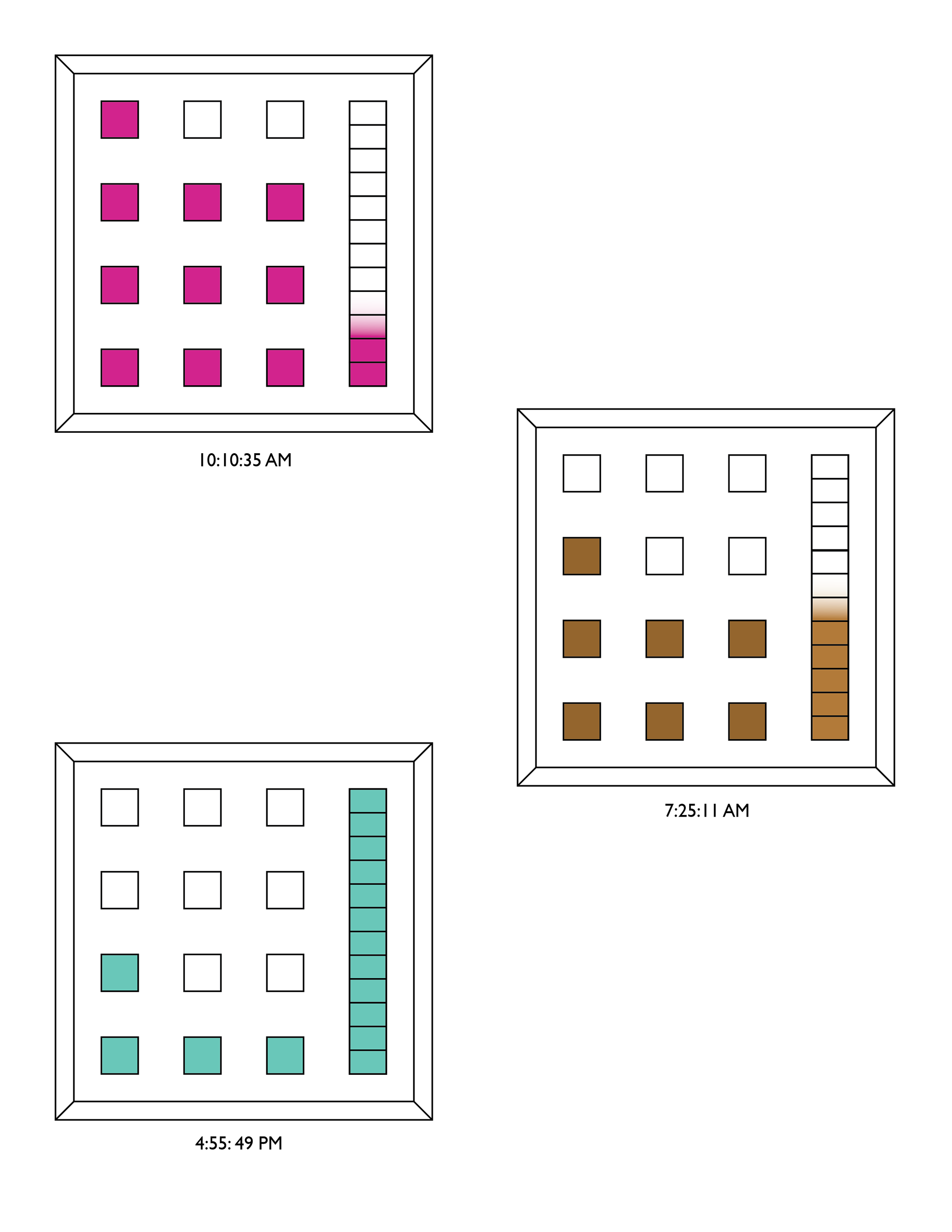

Ultimately, I settled on the idea of a clock that told the approximate time. The clock roughly marked the progression of time and contributed to a sense of ambiance rather than displaying actual numbers.

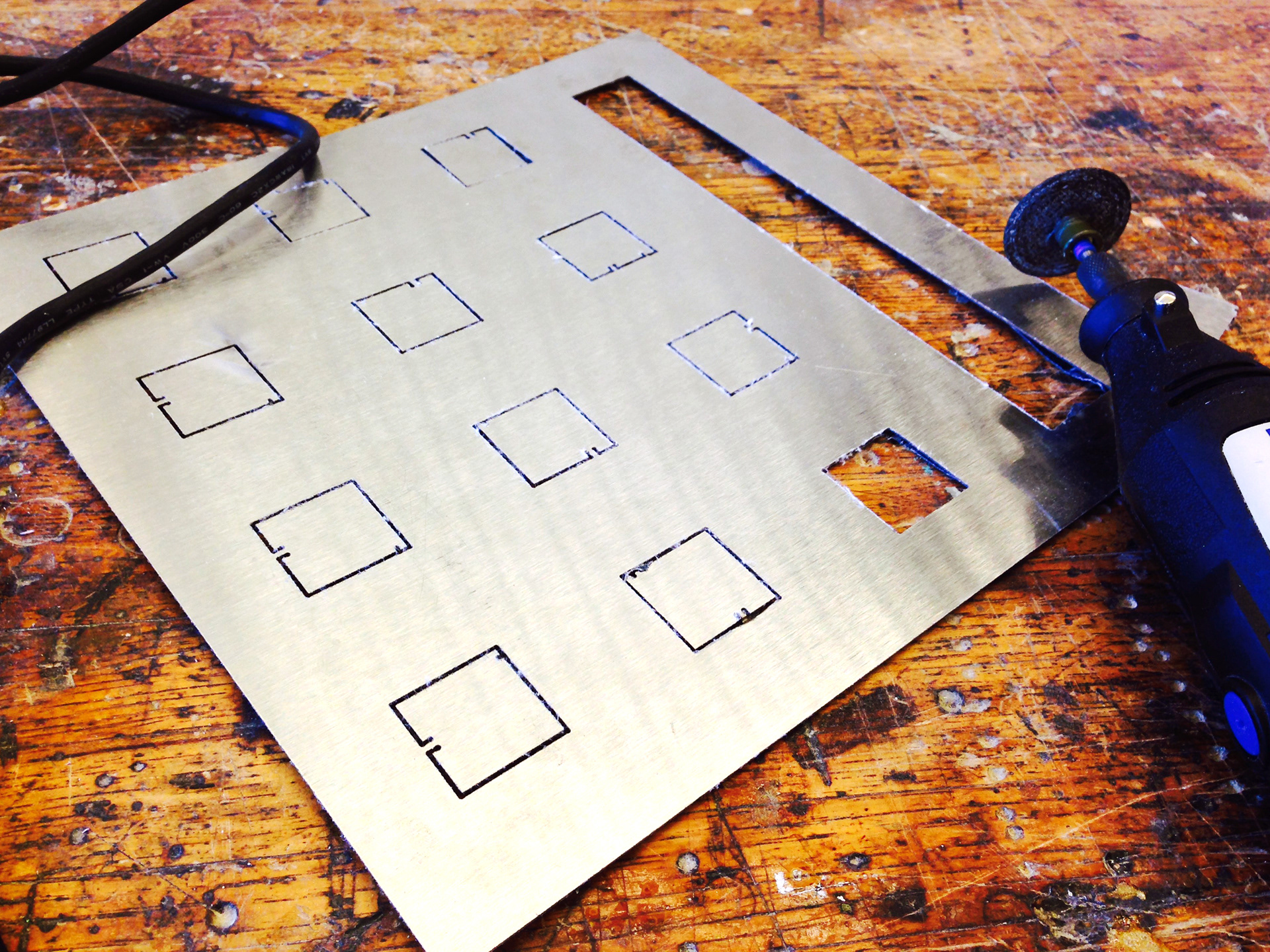

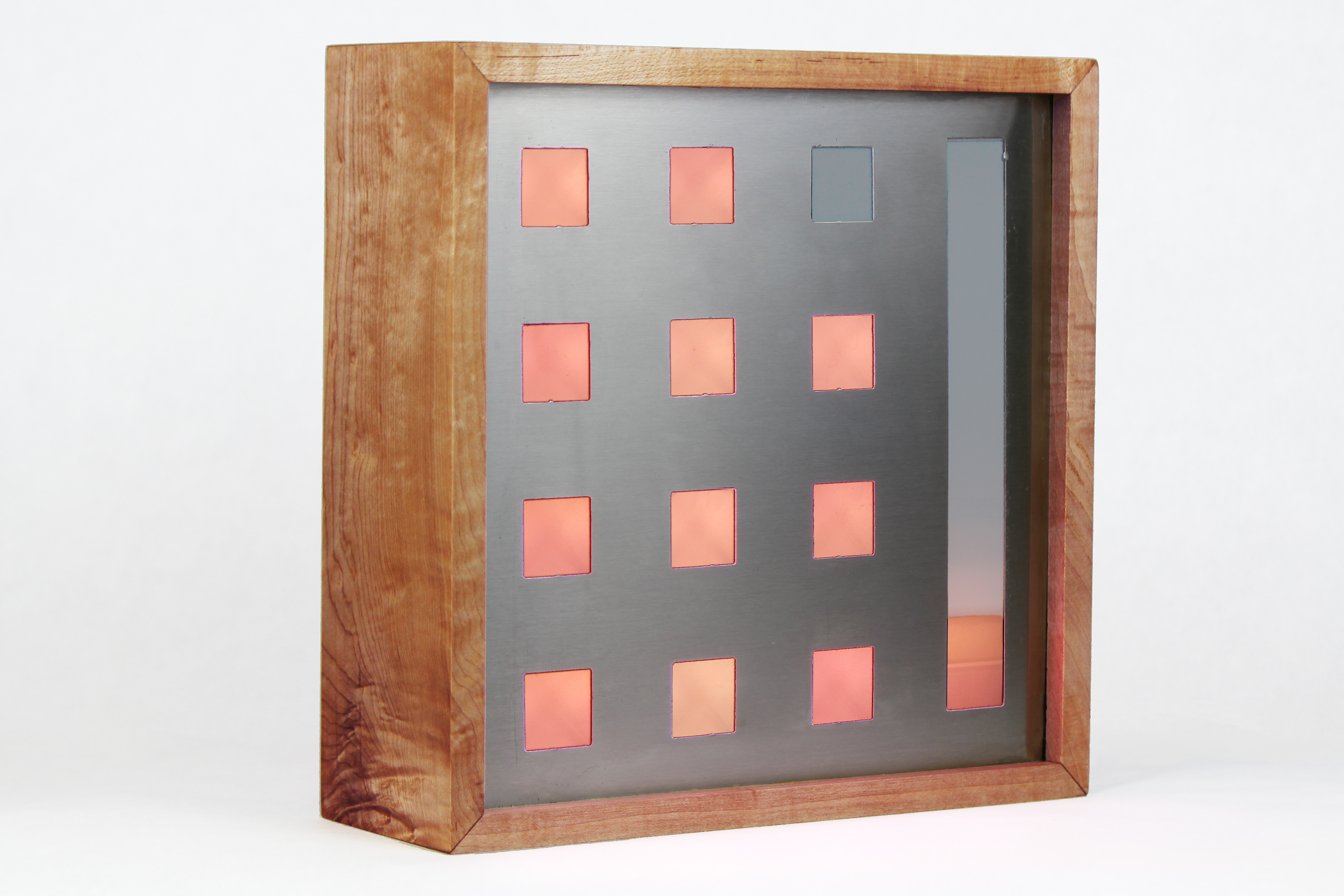

With the idea of Tempo in mind, I began sourcing materials. Lumber came from a tree in my grandparents' backyard and I recruited a friend to help me cut the face pieces on a water jet cutter.

After college, I put the unfinished clock pieces away as I graduated and moved on to other things.

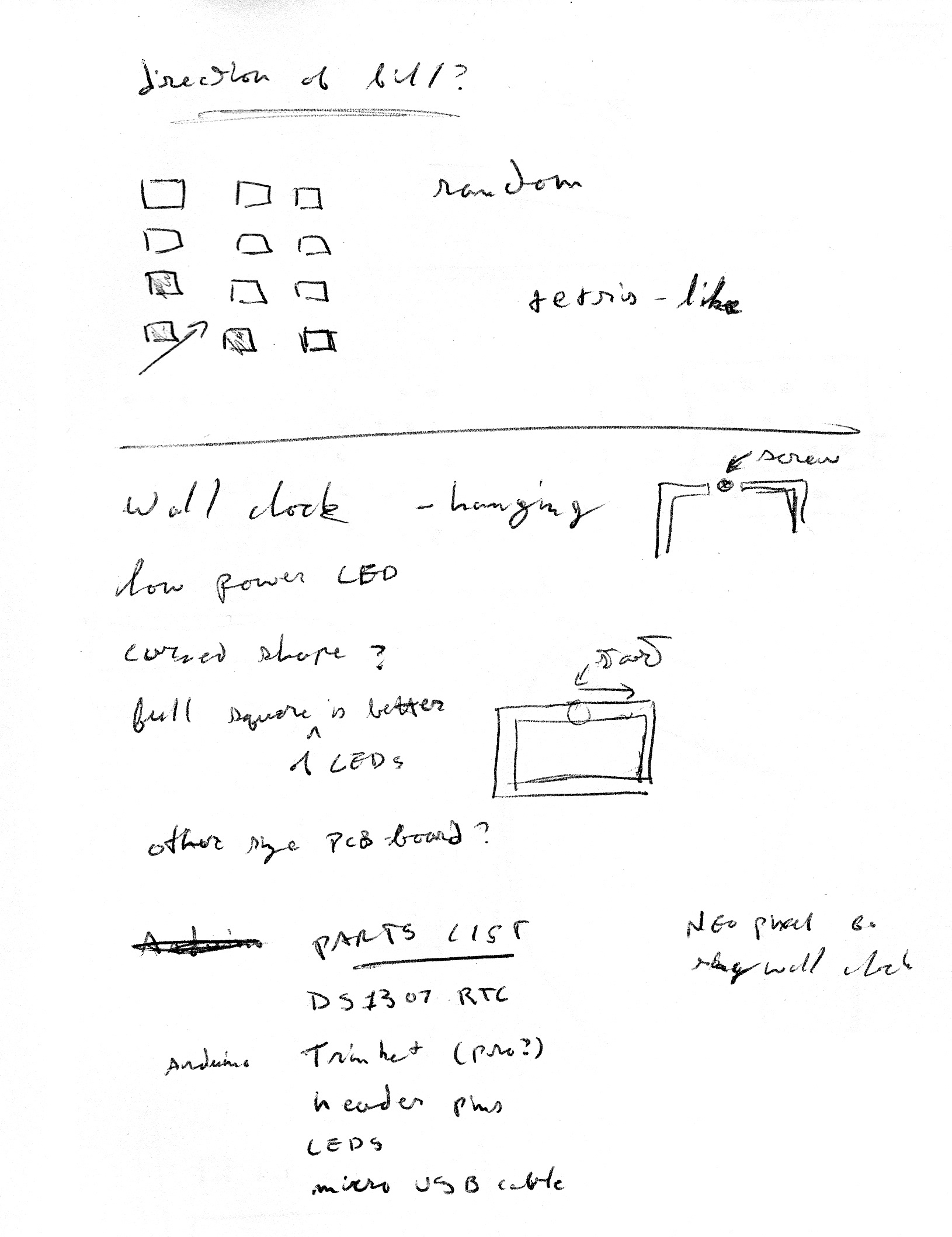

Several years later, I returned to Tempo as the first product to be launched under my Westlake Industries banner. The goal was the same: to fully realize my abstract LED clock, but with a renewed focus on manufacturing it as efficiently as possible.

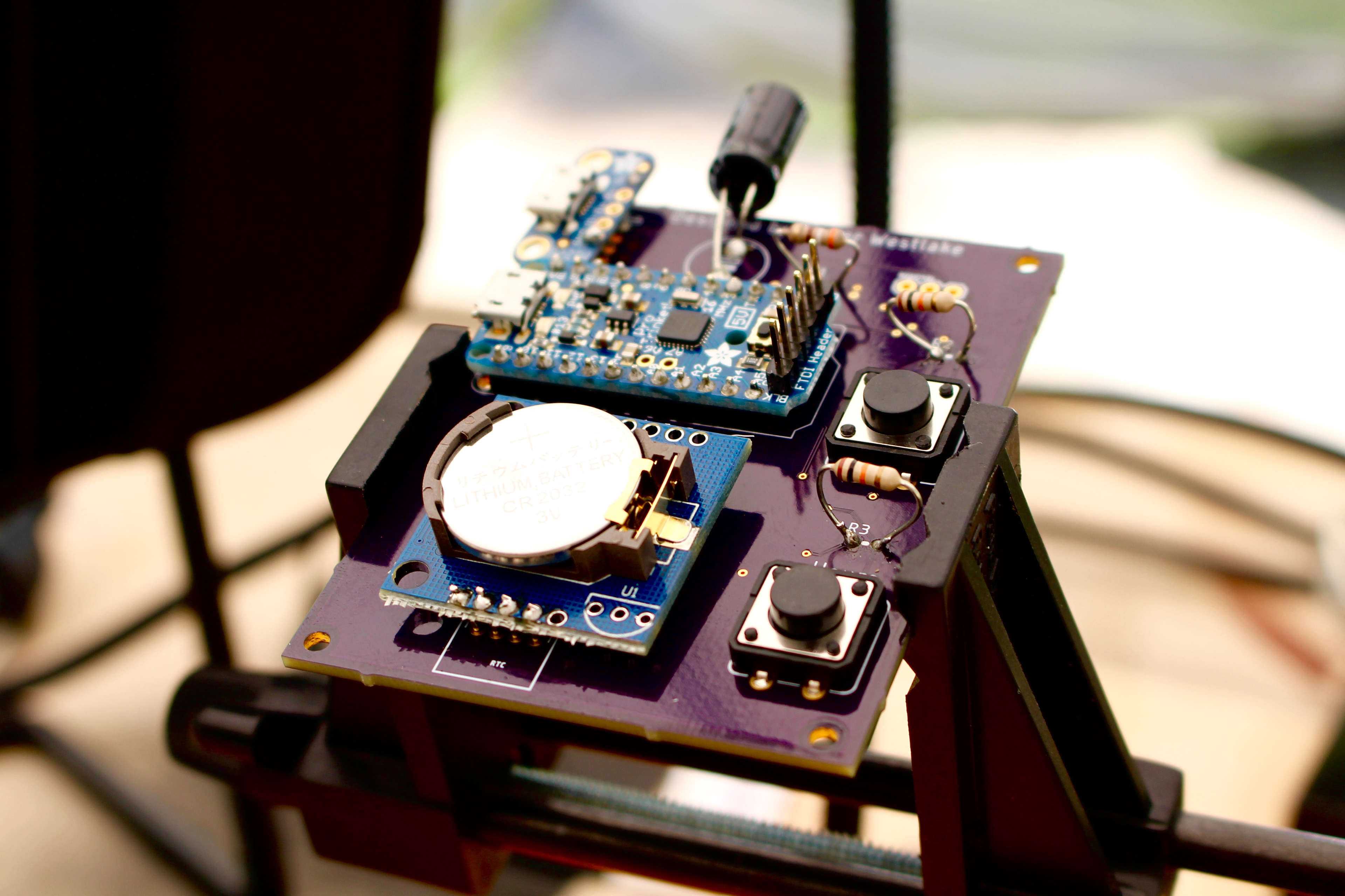

After much trial and error, I successfully coded a working prototype. I designed the circuit board from scratch, but for the first run, the circuit boards were all hand soldered. The board contained a dedicated time keeping module and buttons to change the hours and minutes.

For the LEDs, I sought a design that minimized the amount of soldering and with the efficient wire routing but still fit the arrangement needed. I finally settled on ribbon cables with smallest profile LEDs I could source.

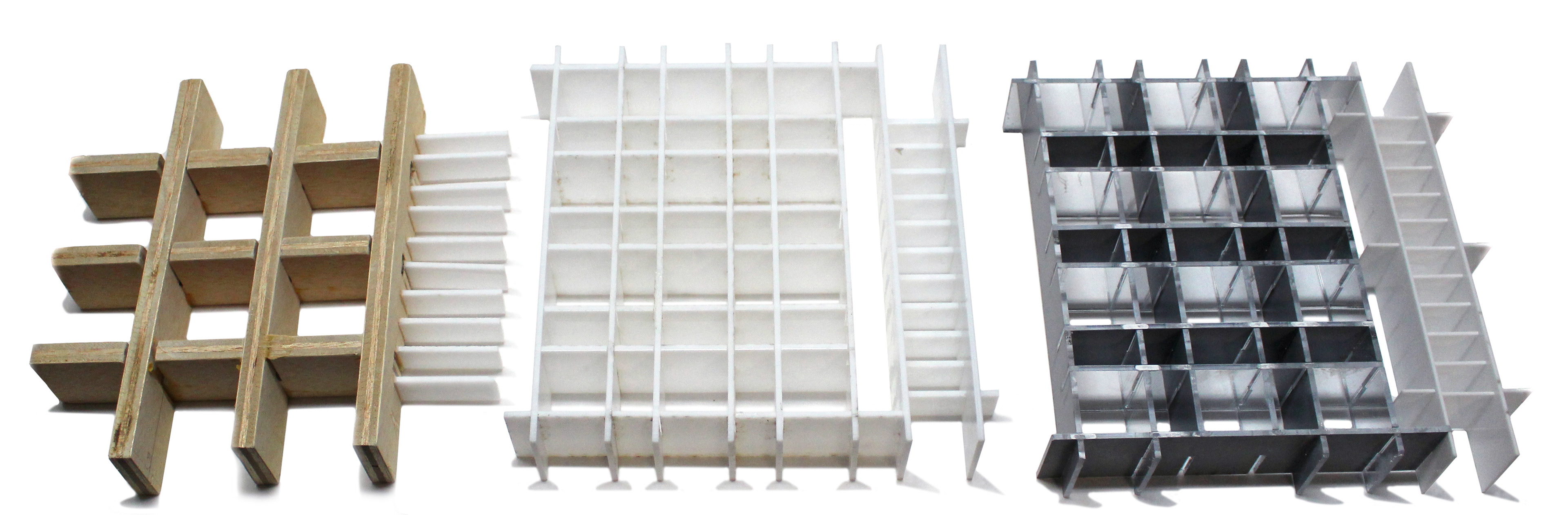

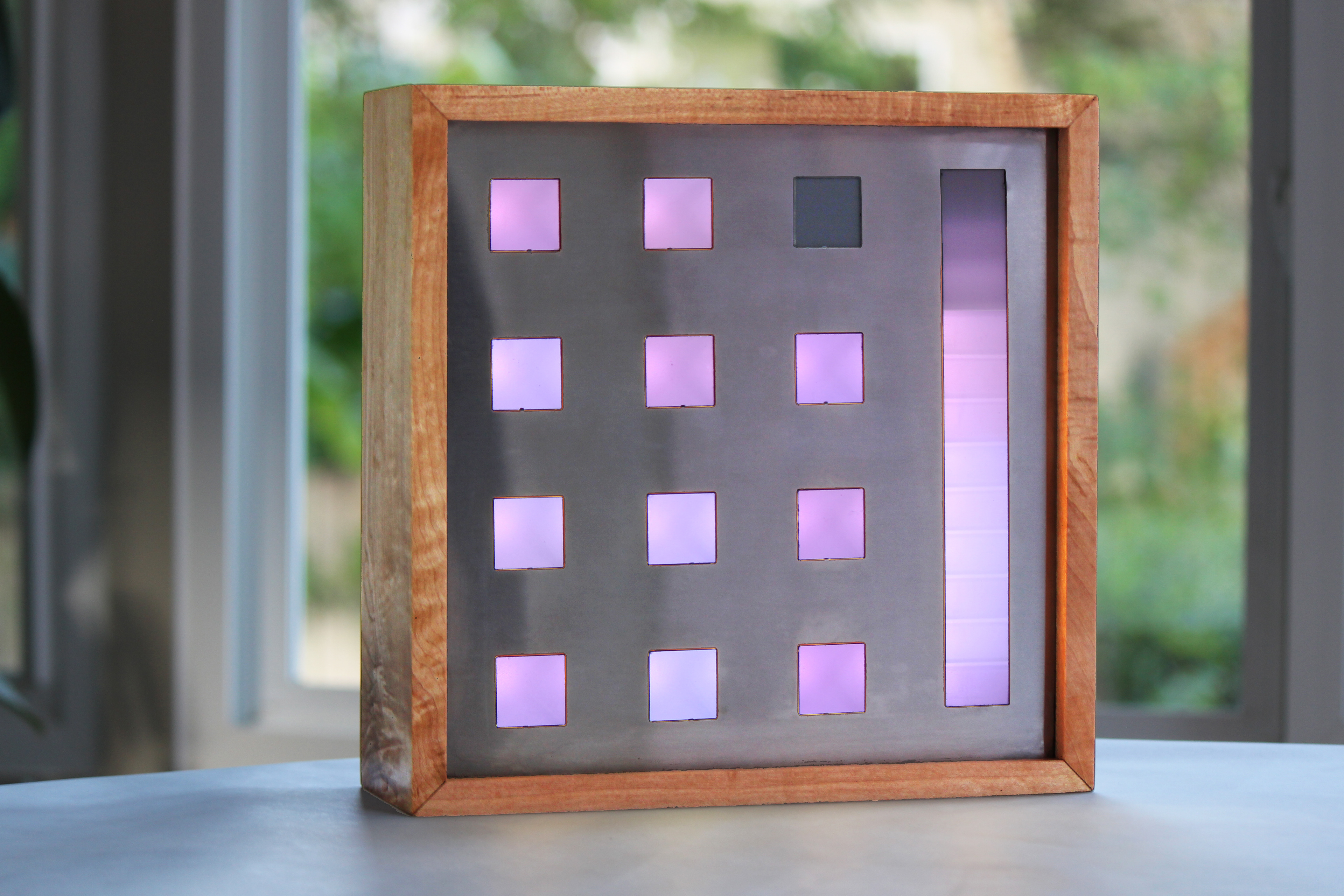

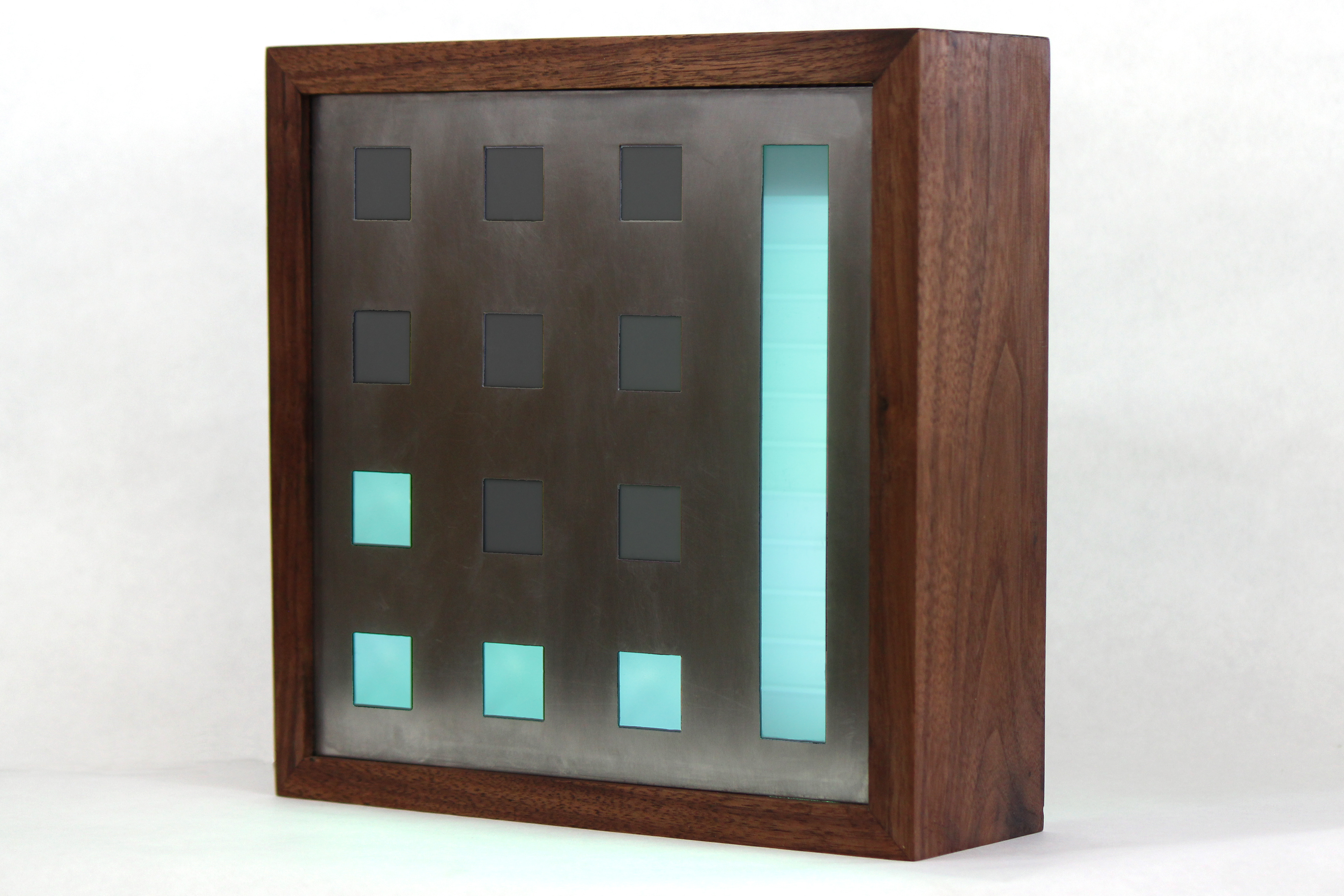

The final task was to create an interior grid to prevent the lights from bleeding into each other. After testing various materials, I ultimately settled on mirrored acrylic for the hours and a translucent white acrylic for the minutes which let just a little bit of light bleed through.

The front was a solid piece of stainless steel backed by translucent plastic and held in place by a solid wood frame. The acrylic grid sat between the steel front and the LED panel. Finally, a piece of plywood covered the back.

I also created new graphics, diagrams, and promotional images to advertise Tempo and explain its unique design.

Ultimately, I offered Tempo in 4 different woods: maple, walnut, cedar, and rosewood. Currently, Tempo is out of production as I work on retooling it to make it better and improve manufacturing efficiency, so stay tuned!